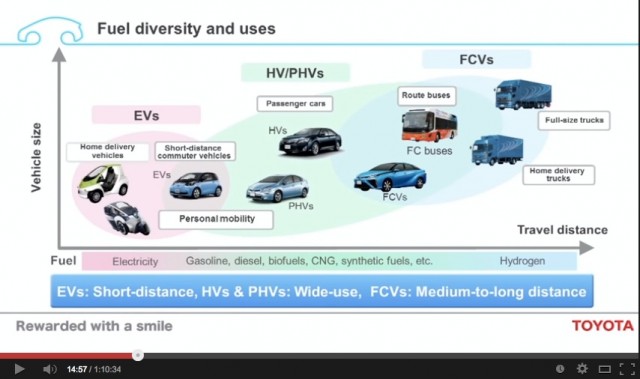

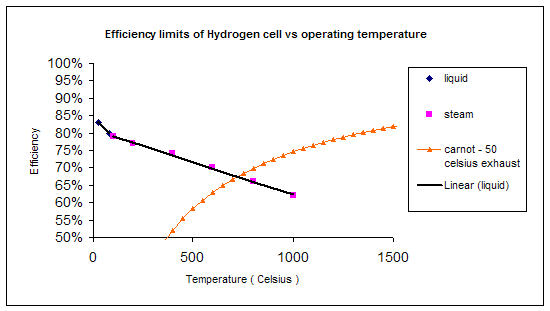

A short animation to explain how a Proton Exchange Membrane Fuel Cell (PEMFC) works. PEM Fuel Cell: How it works Pragma Industries You get get much more information on fuel cells reading. Proton Exchange Membrane (PEM) fuel cells work with a polymer electrolyte in the form of a thin, permeable sheet. Efficiency is about 40 to 50 percent, and operating temperature is about 80 degrees C (about 175 degrees F). pem fuel cell generator hydrogenics fuel cell led pem pem hydrogen cell stack pem stack hydrogen fuel cells custom fuel cell stack hydrogen pem fuel cells fuel cell stack Download: Available on the App Store Available on Android This DOE Hydrogen and Fuel Cells Program activity is focused on the conversion of hydrogen to electrical or thermal power and the use of hydrogen to power vehicles via polymer electrolyte membrane (PEM) fuel cells, for auxiliary power units on vehicles, or for stationary applications. The Fuel Cells subprogram is also pursuing polymer electrolyte membrane (PEM) fuel cells as replacements for internal combustion engines (ICEs) in lightduty vehicles to increase vehicle efficiency and support the goals of reducing oil use in and PEM (Proton Exchange Membrane) fuel cells are lighter, smaller, and more efficient than other types of fuel cell. As a result, over 80 of fuel cells being produced today are PEM cells. Rather, a fuel cell consumes fuel (hydrogen for PEM fuel cells) at the anode and oxygen from the air at the cathode. A catalyst is utilized at the anode to promote separation of. PEM fuel cells within California, starting with relatively high paying fuel cell installation jobs and ultimately progressing to lower paying but longer lasting fuel cell manufacturing jobs. A simplified representation of the SINAVY PEM Fuel Cells' basic function and design is shown in (Fig. 3): the electrochemical element at which the chemical energy is converted into electrical energy is the membrane SINAVY PEM Fuel Cell modules BZM 34 and BZM 120 are. Nedstack is one of the leading PEM fuel cell manufacturers in the world Products Fuel Cell stacks have proven a long lifetime and high energy efficiency in the field. Learn more about the following types of fuel cells. Polymer electrolyte membrane fuel cells Polymer electrolyte membrane (PEM) fuel cellsalso called proton exchange membrane fuel cellsdeliver high power density and offer the advantages of low weight and volume compared with other fuel cells. The Horizon H30 PEM Fuel Cell is a 30 Watt, air fed air cooled, selfhumidified hydrogen fuel cell suitable for many small projects and uses. Because this fuel cell is air cooled there is not need for large, complicated, and expensive water cooling systems. Horizon HSeries PEM fuel cells are semiintegrated, efficient, reliable systems that minimize the use of peripherals. The layout of an integratedfuel cell is depicted in Fig. SETUP OF A SINGLE INTEGRATED FUEL CELL Conventional PEM fuel cells consist of a polymer electrolyte membrane (PEM). Explore the latest articles, projects, and questions and answers in PEM Fuel Cells, and find PEM Fuel Cells experts. Proton Exchange Membrane (PEM) fuel cells in particular are experiencing an upsurge. They have high power density and can vary their output quickly to meet shifts in power demand. Until now, there has been little written about this important technology. This book lays the groundwork for fuel cell engineers, technicians and students. Global producer of hydrogen PEM fuel cell and integrated products up to 5000W, with a strong focus on commercialization across several industries including outdoors, back. The Reversible PEM Fuel Cell combines the functions of an electrolyzer and a fuel cell into ONE device. When applying an electrical current the device acts as an electrolyzer that produces hydrogen and oxygen from deionized water. Explore the global market for materials for proton exchange membranes and membrane electrode assemblies for PEM fuel cells. Applications for PEM fuel cells The PEM fuel cell can be used for a great variety of applications such as mobile phones, cogeneration of power and heat or drive trains for automobiles. PEM fuel cell drive systems are now demonstrated in many prototype vehicles. A single fuel cell consists of a membrane electrode assembly (MEA) and two flowfield plates delivering about 0. 5 and 1V voltage (too low for most applications). Just like batteries, individual cells are stacked to achieve a higher voltage and power. Proton exchange membrane (PEM) fuel cells work with a polymer electrolyte in the form of a thin, permeable sheet. Proton exchange membrane (PEM) fuel cells operate at relatively low temperatures and are composed of two electrodes and a conductive elecrolyte. Research Overview; Fuel Cells; Energy demands are growing and polymers play an integral role in advancing energy generation technologies. Currently we focus on synthesizing and characterizing polymer electrolyte membranes for fuel cells: both acidic and alkaline environments. Proton Exchange Membrane or PEM Fuel Cells are considered to be the most versatile type of fuel cells currently in production. They produce the most power for a given weight or volume of fuel cell. PEMFuel Cells Fuel cell systems are typically running at temperature up to 90 C, depending on the field of application. The operating pressures were also useorientated in the range of up to 2 bars. A fuel cell is a device that converts chemical potential energy (energy stored in molecular bonds) into electrical energy. A PEM (Proton Exchange Membrane) cell uses hydrogen gas (H2) and oxygen gas (O2) as fuel. The products of the reaction in the cell are water, electricity, and heat. There are many types of legacy fuel cells such as proton exchange membrane (PEM), molten carbonate fuel cells (MCFC), direct methanol fuel cells (DMFC) and solid oxide fuel cell (SOFC). The table below lists characteristics of these various fuel cell approaches. The proton exchange membrane fuel cell (PEMFC) uses a waterbased, acidic polymer membrane as its electrolyte, with platinumbased electrodes. PEMFC cells operate at relatively low temperatures (below 100 degrees Celsius) and can tailor electrical output to meet dynamic power requirements. Fuel Cells is a platform for scientific exchange in a diverse interdisciplinary field. All related work in chemistry, physics, materials science, chemical engineering, electrical engineering, and mechanical engineering is included. Polymer Electrolyte Membrane (PEM) fuel cells used in automobilesalso called Proton Exchange Membrane fuel cellsuse hydrogen fuel and oxygen from the air to produce electricity. A simplified representation of the SINAVY PEM Fuel Cells basic function and design is shown in (Fig. 3): the electrochemical element at which the chemical energy is converted into electrical energy is the membrane electrode unit. It consists of the polymer electrolyte. Fuel cell testing equipment for PEM. Our EvaluatorLT test stations are ideally designed for the specific testing requirements of low temperature fuel cells. They provide a wide range of individual testing options. With these testing systems, PEM fuel cells as well as their components can be evaluated within a temperature range from 40 C up to 250 C and a power range between 1 W and 250 kW. A polymer electrolyte membrane (PEM) fuel cell in operation is always between having too much water and not having enough water. Fuel cell performance is characterized by its polarization curve, that is, a plot of cell potential versus current density. PEM fuel cells use a proton conductive polymer membrane as electrolyte. PEM stands for Polymer Electrolyte Membrane or Proton Exchange Membrane. How Fuel Cells Work The most common type of fuel cell for vehicle applications is the polymer electrolyte membrane (PEM) fuel cell. In a PEM fuel cell, an electrolyte membrane is sandwiched between a positive electrode (cathode) and a negative electrode (anode). PEM fuel cells supplied by Siemens Marine Solutions deliver an atmospheric airindependent, noiseless propulsion solution for power generation on board which can extend the dive time by several weeks. Performance, efficiency and safety for extended underwater operations. Fuel Cell ModulesThe fuel cell module is only one component in a fuel cell system. A complete system will also include a control system, power conditioning and fuel delivery to name [ The NM5 PEM fuel cell stack developed and produced by ElringKlinger was optimized to ensure a low pressure drop in the reaction gases and a long service life. The Horizon H5000 PEM Fuel Cell is a 5 kW, air fed air cooled, selfhumidified hydrogen fuel cell. Because this fuel cell is air cooled there is no need for large, complicated, and expensive water cooling systems. Horizon HSeries PEM fuel cells are semiintegrated, efficient, reliable systems that minimize the use of peripherals. polymer electrolyte membrane fuel cells (PEMFCs). A nonlinear controller is designed based on the proposed model to prolong the stack life of the PEM fuel cells. Since it is known that large devi Global PEM Fuel Cells Materials Market: Inclusive Insight. The global proton exchange membrane (PEM) fuel cells materials market is currently making headway to secure its place on a rising trend on the back of PEM and membrane electrode assembly (MEA) components. PEM (Proton Exchange Membrane) fuel cells are lighter, smaller, and more efficient than other types of fuel cell. As a result, over 80 of fuel cells being produced today are PEM cells. Find great deals on eBay for pem fuel cell. PEM automotive fuel cell system, based on 2015 technology and projected to a manufacturing volume of 500, 000 units per year [2. Results from the analysis were communicated to FCTO at Hydrogen Fuel Co has been involved in alternative fuels for over 3 decades and holds free public seminars to educate the public on how they can benefit from. Fuel cells are electrochemical energy conversion devices that convert hydrogen and oxygen into water, producing electricity and heat in the process and providing fuel efficiency and reductions in pollutants. Demand for this technology is growing rapidly. Fuel cells are being commercialized for stationary and portable electricity generation, and as a replacement for internal combustion engines. Fuel cells can be used in a wide range of applications, including transportation, material handling, stationary, portable, and emergency backup power applications. Fuel cells have several benefits over conventional combustionbased technologies currently used in. Ballard Power Putting Fuel Cells to Work. Ballard's fuel cell power products offer a number of important advantages. Proprietary MEA; Proven Durability.